Sustainability

Our sustainability promise

With LTwo® and Lumami®, apl doesn’t just make lighting — we make a modular, upgradeable, and circular lighting system that’s better for people, buildings, and the planet at every stage of its life. We transform lighting from a disposable fixture into a circular, upgradeable building component — reducing environmental impact at every stage, from sourcing to second life.

In a market where everyone claims “green”, we try to do our best through a smart design, which can help all of our stakeholders to be more sustainable. Still we know, the effects are hard to measure. We hope we can significantly contribute through our philosophy across the life-cycle of our products.

apl Sustainability Story – LTwo & Lumami

From source to second life – Minimising embodied and operational carbon

1. Supply – Responsible sourcing of materials

- Minimal material footprint: Following the concept of ideality and miniaturization, we have minimized the material footprint of our products, using up to 90% less material and volume than comparable luminaires.

- Carbon friendly logistics: A compact form factor means less raw material, less packaging, and lower transport emissions from day one. We try to source key components and services, whenever possible, within our region or within Europe.

- Sustainable components: We prefer recyclable metals, low-impact plastics, and eco-certified suppliers.

2. Manufacturing – designed for less waste

- Standardized parts: High part commonality across the product family reduces tooling, material diversity and means minimal scrap. Fewer SKUs lead to optimized production runs.

- Low carbon design: Compact form factor and fewer components mean less embodied carbon.

- Cradle-to-cradle mindset: Products are designed for disassembly and material separation.

3. Installation – Low impact integration:

- Integration without reconstruction: The products fit existing ceiling, wall and track systems, avoiding demolition or heavy structural modifications.

- Lightweight modules reduce packaging materials, transport emissions and make handling easy.

4. Use – Efficient and adaptable performance

- No lumens wasted: Precision optics direct light exactly where needed, reducing over-illumination and operational carbon.

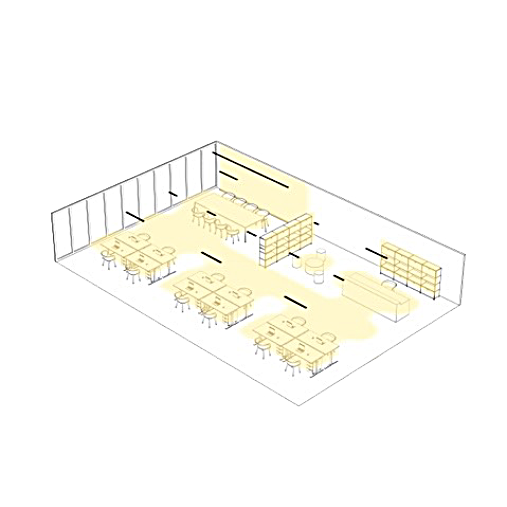

- Right light, right place: Zonal lighting approach, based on the modular flexibility, minimizes number of luminaires required, lowering energy consumption and initial investment. Modularity means lighting layouts can be adapted to new uses without wasteful reconstruction.

- Click here to learn more about the right light, right place concept

- Light engine efficiency at 142 to 180 lm/W, depending on CRI and operating mode, while the optical modules have an efficiency of 59% to 93%, depending on the optics.

- Upgrade-ready: Modules can be swapped or updated without replacing the whole luminaire, extending system life.

- High-quality LEDs (L80B10 >60,000 h) ensure longevity and stable performance, exceeding green building lighting standards.

- DC lighting topology (remote driver, multiple fittings per driver) cuts e-waste and boosts system efficiency.

5. Maintenance – Replace the part, not the whole

- Separation of light source and electronics: Only the worn component is replaced, avoiding full-unit waste.

- Easy access & plug-and-play: Reduces labour time and transport for service calls.

- Standardized parts: Simplifies spare parts logistics, reducing inventory waste.

6. Facility Management – Lower cost of ownership

- Hybrid compatibility: Works across different spaces and systems, reducing need for multiple lighting SKUs.

- Reduced storage footprint: Fewer product types to stock; lower risk of obsolescence.

- Adaptable over time: Lighting layouts can be reconfigured for new uses without major rebuilds or re-wiring. Further reduces obsolence risk through upgrade paths and lowers carbon impacts from reconfiguration.

7. Re-Use – Extending product life

- Relocatable modules: LTwo® can move with the building user to a new space.

- Creative re-use: Lumami® and LTwo® modules can be re-housed in new decorative fixtures, from acoustic panels to custom designs.

- Design for longevity: Durable materials and replaceable modules support multiple use cycles, deferring the carbon footprint of replacement.

8. End of life – Closing the loop

- Minimal waste: By the time a product reaches end-of-life it comes with minimum waste. Aluminium: 124 g/m, Plastic: 49.5 g/m – all recyclable and easy to disassemble. Only 5,5gr/m of non-recyclable electronics (only 3% of product weight).

- Material separation: Metals, plastics, and electronics are easy to disassemble for recycling.

- No bonded composites: all non-electrical components recyclable, 87% as high-purity mono-materials.

- Circular partnerships: Potential for take-back schemes with OEMs or facility managers.

right light, right

place concept

Let us explain what we do and how we help to protect our environment and your investment by a simple example.